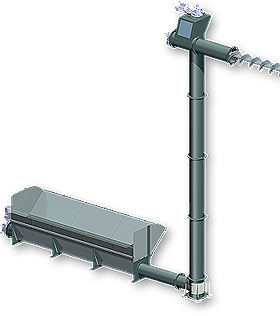

Wood chips or pellets are filled into the through and transported via the vertical feeding screw up to a max. height of 10 m. The vertical spreading auger inside the silo optimizes the silo´s filling volume.

Max. transport capacity is 60 m3/h, with available double screws up to 120 m3/h.

Advantages

- Individually configured

- Robust

- Reliable

- Height up to 10 meters

- Corrosion-resistance due to completely galvanised casing for permanent outside installation

- Optimal usage of silo volume through horizontal spreading auger (max. silo width 12 m)

Variations

Filling trough in duct

If necessary the filling trough can be installed in an under-floor shaft - allowing to cover the whole surface (e.g. to be driven on).

Horizontal delivery over long distances

Transportation of fuel over distances more than 6 m (from the filling trough to the vertical screw conveyor) is possible. A maximum length of 14 m can be achieved using transfer systems.

Container as fuel storage

Often separate storage containers are used outside the building. Using a vertical filling system enables a high reservoir construction for an optimal spacesaving storage volume.

![]()