Innovation by System KURRI

The requirements in the development of the new control system were energy saving, connectability, serviceability and efficiency.

The innovative control system with electronic control features a lambda probe (λ) and several temperature gauges for the control of operating load and maximum temperature and optimizes the efficiency of your heating system.

This control can be used both for our System KURRI heating systems and boilers for other providers. Retrofitting is generally possible.

By use of the λ probe in the exhaust stream (temperature measurement at the end of the combustion chamber) a constant CO2 values and the security of the ignition is ensured. A frequency monitor automatically adjusts the precise combustion air supply and the provision of fuel - with minimum electrical consumption. The system also includes a CAN bus, the other (up to 255) controls and an Internet interface for home automation with standards also used by industry 4.0.

The cabinet ensures minimum emissions and maximum efficiency

All electric cabinets are equipped with modern programmable logic controllers (PLC) and depending on the requirements with corresponding automatic control systems to ensure compliance with emission regulations.

All drive systems that are automatically adjusted are equipped with energy-saving electronic speed control devices.

Convenient Remote Control and Monitoring

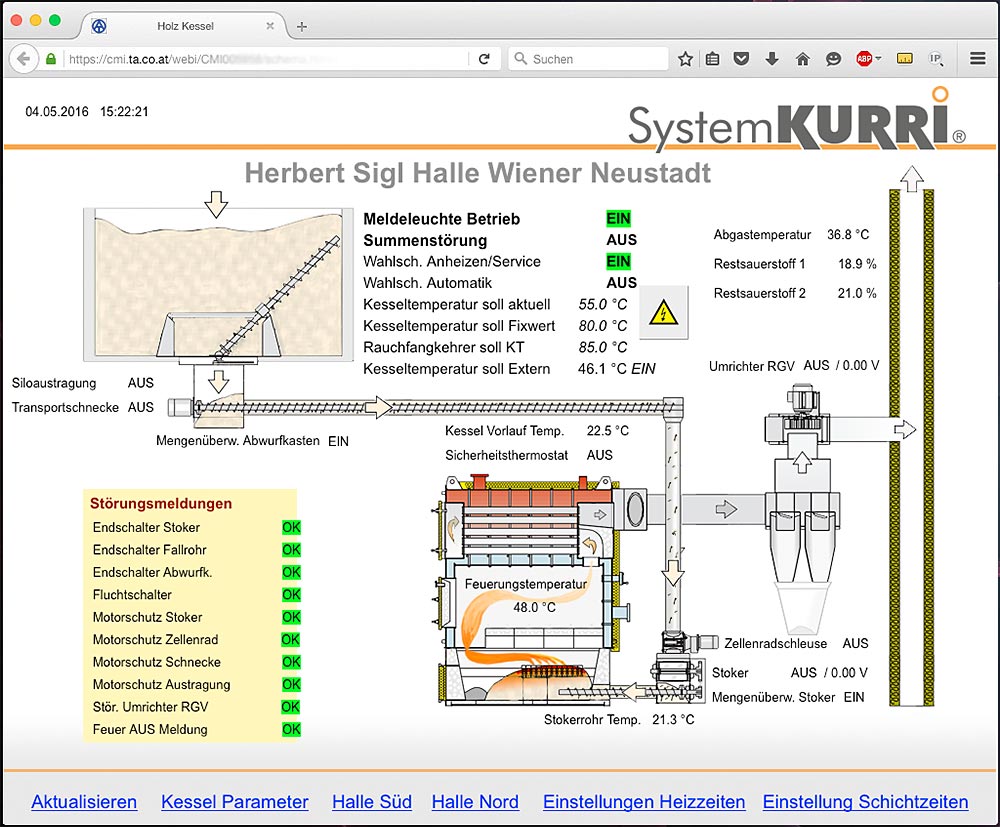

A highly encrypted Internet connection enables to control the heating systems at any time using a web browser.

The connection between the CAN bus of the heating controller and an existing Ethernet LAN with WWW connection offers many new possibilities in terms of industry 4.0 requirements:

- Visualization of the operating state of the vessel with all the important parameters

- Perform remote maintenance by the producer or service technician with access to all boiler parameters and the ability to update the control program

- Information about the operating status / error of the boiler and submission of errors via email. The system can optionally be equipped with a GSM module to send to SMS, the SIM card is provided by the customer / operator.

Screenshot of web-interface with schematic overview of all important parameters:

Examples and references from practice

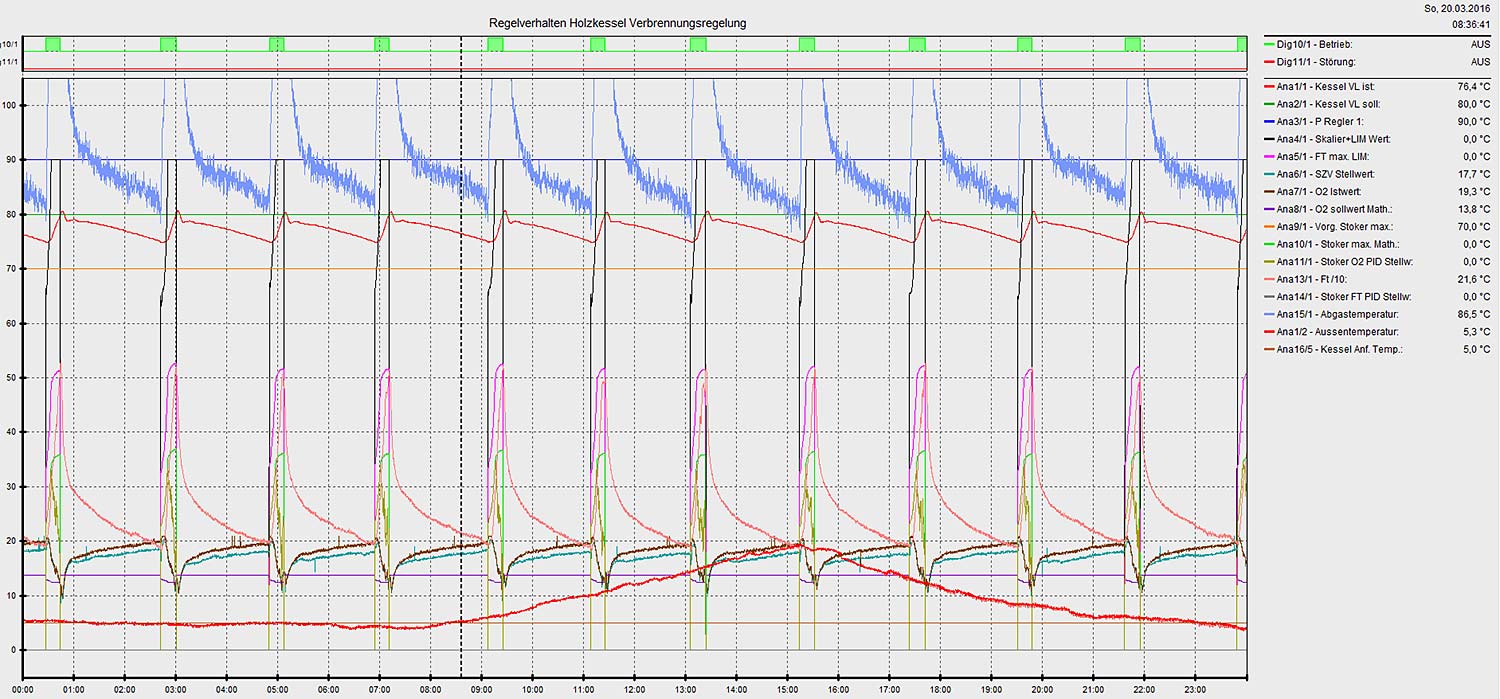

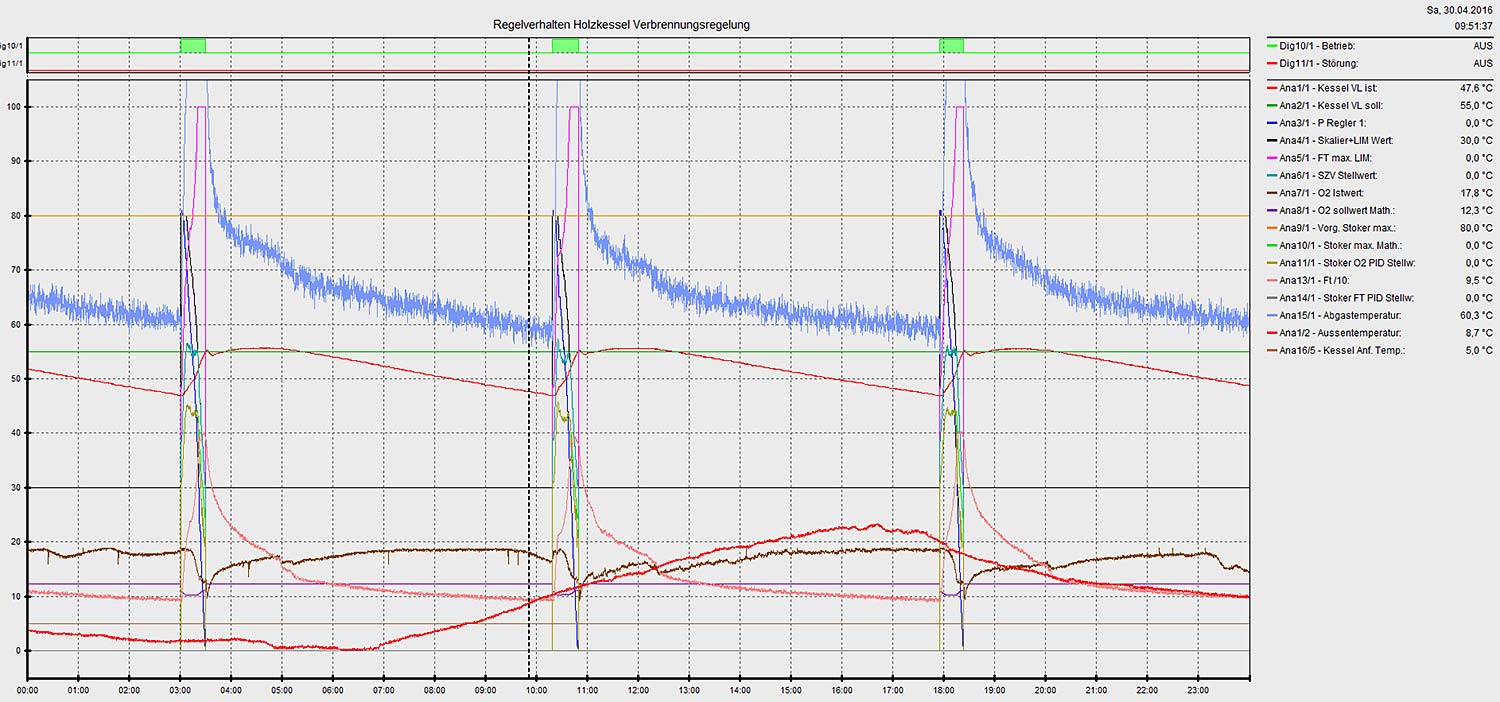

The switch-on frequency of the heating in an industrial building, commercial operation or in buildings of the administration can be positively influenced by using interconnected control systems. Thus the boiler is in low-load operation on weekends or holidays / vacation days only 3 times a day, but without control (with fixed boiler flow temperature) up to 12 times a day.

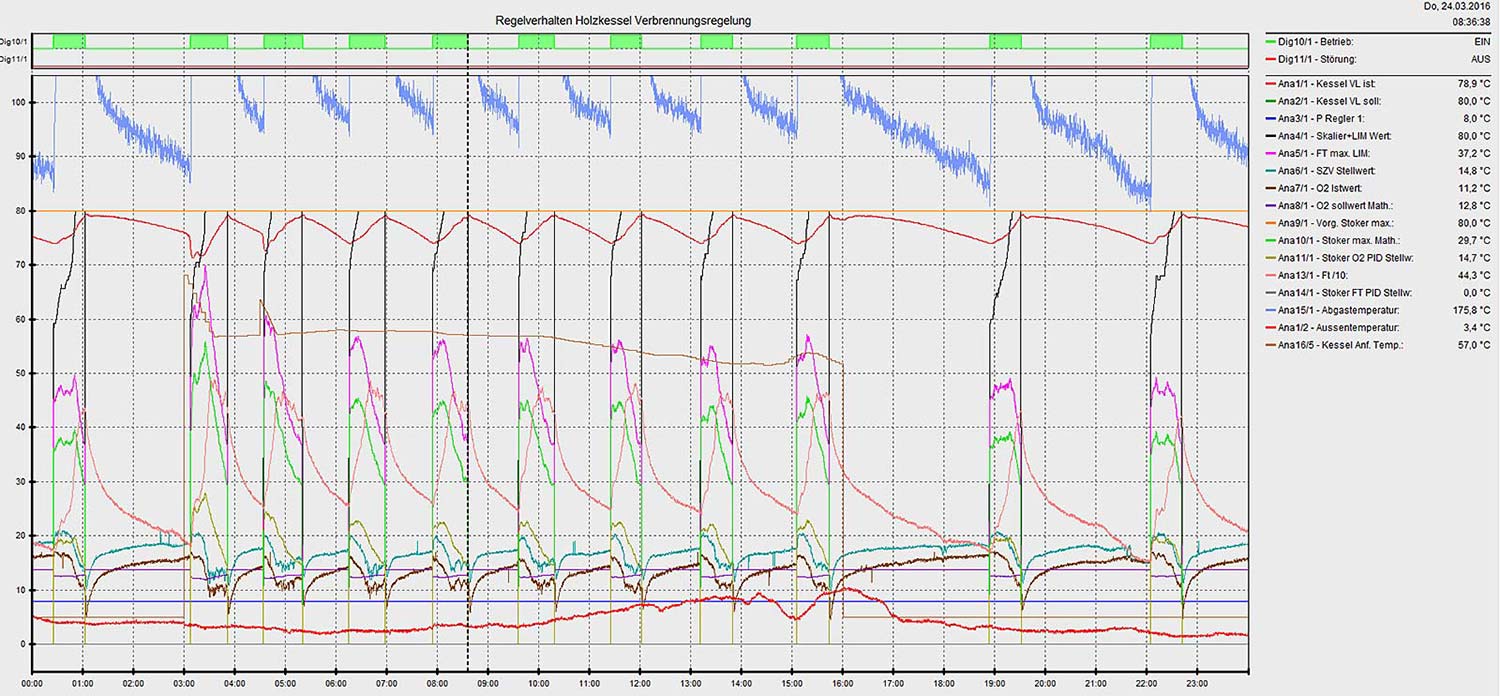

Chart 1: boiler without interconnected building control in low-load operation:

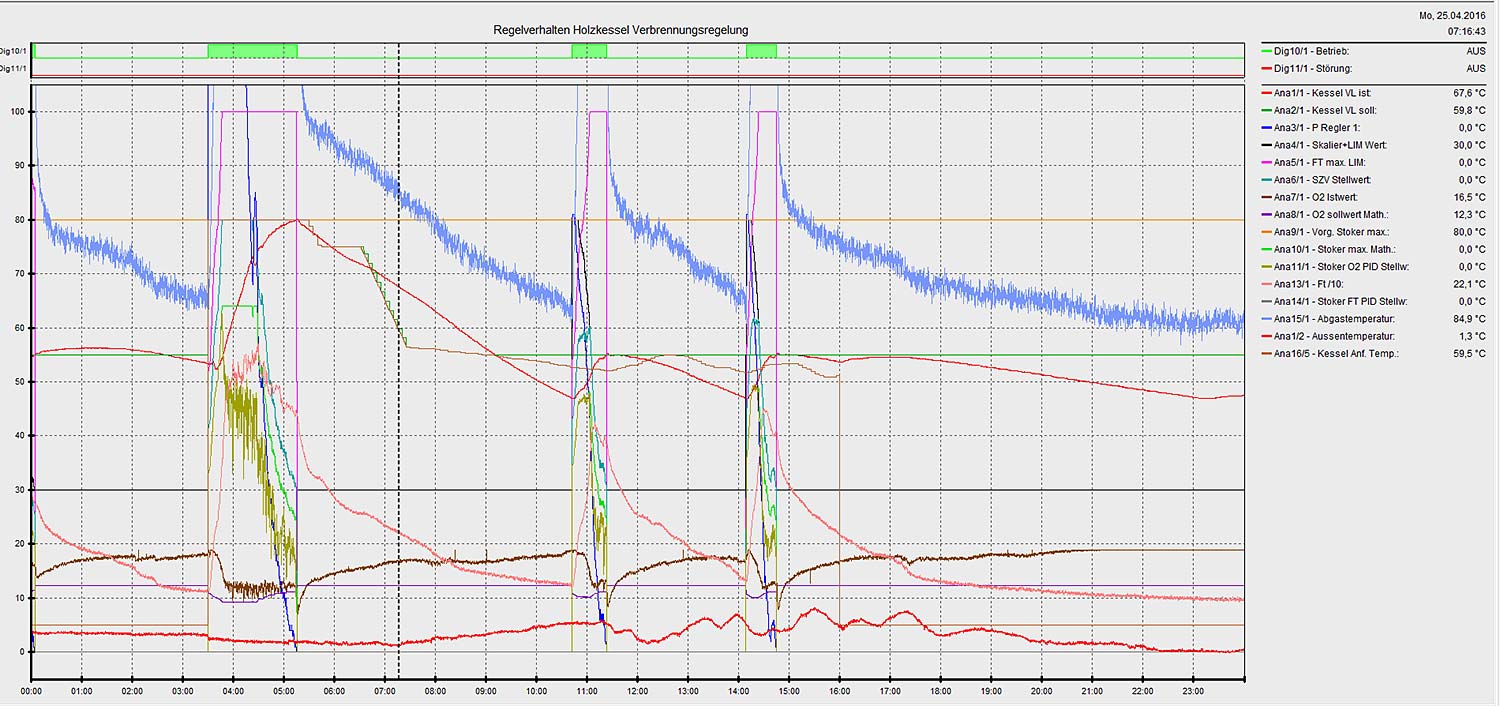

Chart 2: boiler with interconnected control system in low-load operation:

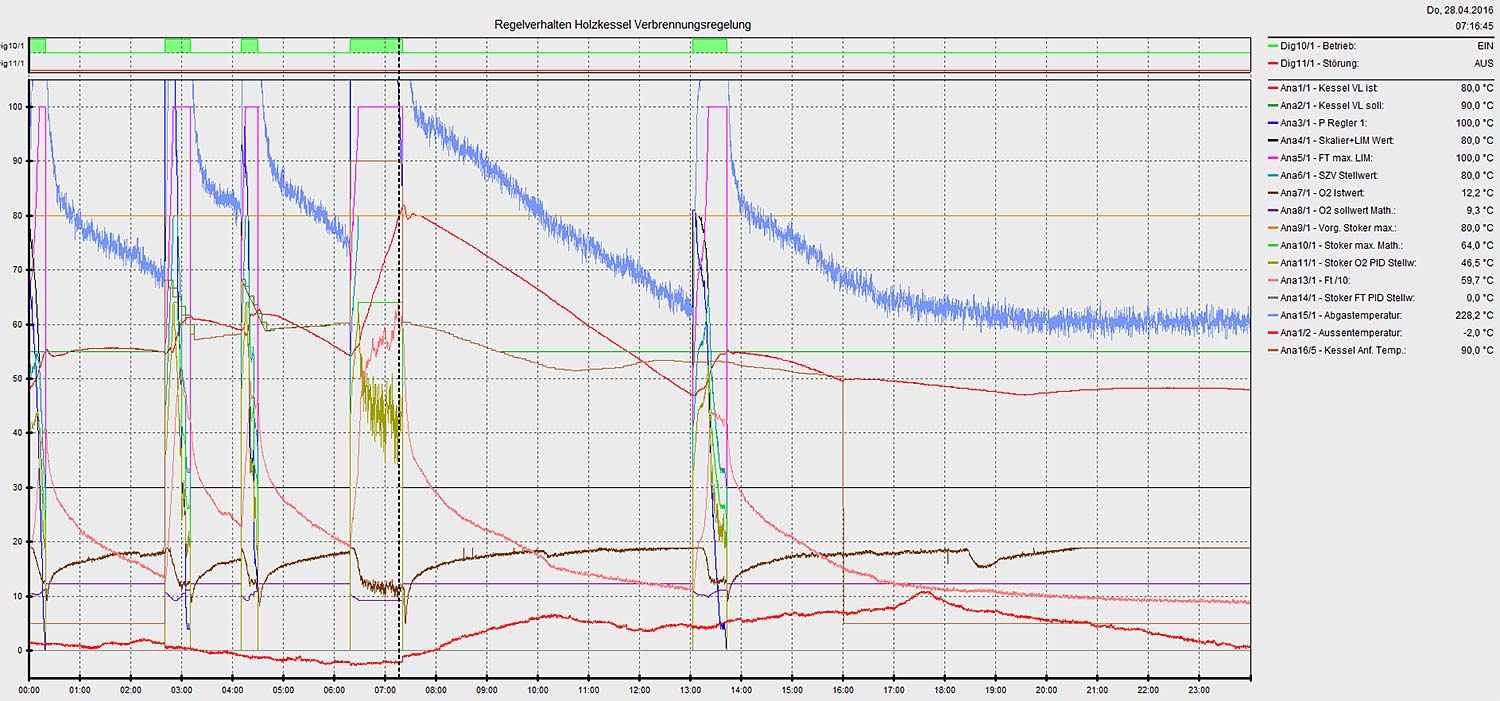

The building control system influences the boiler in heating mode and in normal operation so that at the right time from the comfort temperature is ensured with minimum fuel expense. This saving potential is clearly visible on the bright red line the outside temperature relative to the dark red of the boiler temperature in the comparison of chart 3 (without involvement of building control in the boiler control) to chart 5 (with integration of building control technology).

Chart 3: boiler without building control in normal load operation:

Chart 4: boiler with integrated building control, on a monday:

Chart 5: boiler with integrated building control on a weekday with large outdoor temperature changes: